Advanced IC packaging and integration

The future of semiconductors is empowered by glass

In the era of digitalization and AI, these megatrends are pushing the boundaries of technology. Today’s world runs on computing power. Applications like HPC/AI, autonomous driving, satellite communications, advanced mobile technology, medical diagnostics, and IoT are driving the need for innovative redesigns of IC packages. Advancing the pace of Moore’s Law is only possible with new materials. High-tech glass will play a vital role in keeping the pace for the semiconductor industry and enabling major trends like AI. With a proven track record in delivering mind-blowing glass types for more than 140 years, SCHOTT collaborates on ambitious IC packaging by enabling high-density interconnects at both wafer and panel levels. Discover our broad portfolio of semicon-grade flat glass solutions designed for permanent and temporary applications in semiconductor devices and processes and get in touch with us to make a difference - even in your most challenging projects.

Precisely performing glass solutions

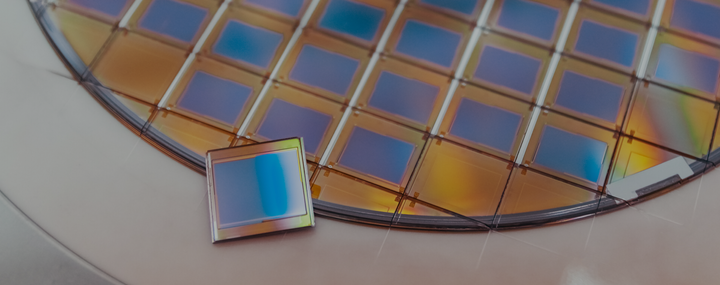

SCHOTT offers high-end glass panels and wafers with a wide variety of thermal, mechanical, and electrical properties, all adhering to SEMI industry quality standards. Our extensive range of glass types and thicknesses, combined with outstanding bulk and surface quality, positions SCHOTT as a preferred supplier. We deliver scalable, high-quality solutions tailored to the needs of the semiconductor industry, ensuring reliability and efficiency in every application.

Leading the ways of technological progress

Solutions for the advancing semiconductor field

Versatile glass solutions for high-tech applications

SCHOTT offers a range of materials with exceptional properties, catering to diverse high-tech applications. Our core portfolio supports thicknesses ranging from below 200 µm to several millimeters, with CTEs (Coefficient of Thermal Expansion) between 3 and 10 ppm/K and capabilities beyond based on our glass technologies. Featuring ultra-low total thickness variation (TTV) as low as < 0.5 µm for advanced applications and smooth surface quality with roughness less than 1 nm, SCHOTT glass ensures precise, reliable, and high-performance solutions for advanced semiconductor technologies.

Applications for the semiconductor industry

The SCHOTT tradition of innovation in the semiconductor industry

Since its inception, SCHOTT has been at the forefront of materials science, continually pushing the boundaries of technology. Our recent advances in patterned glass wafers and an expanded portfolio of glass substrates are an example of this legacy. These innovations are revolutionizing chip packaging with improved performance and miniaturization, meeting the demanding requirements of the next generation of semiconductor technologies. Our pioneering spirit drives us to deliver innovative solutions that foster progress in the ever-evolving electronics industry. Discover more about our breakthroughs in the press releases linked below.

Would like to be inspired how glass in Semicon can be a solution for you? Let´s talk!

Whether you need more information, samples, a quote, or advice for a project, we would be delighted to talk to you.