Semiconductor & Datacom

Unlock the future with specialty materials

Transforming semiconductors with specialty materials

SCHOTT contribution to advanced semicon packaging and front-end semiconductor manufacturing processes

At SCHOTT, our passion for innovation pushes the boundaries of technology. With world-class R&D expertise and an unmatched portfolio of specialty materials drive, we drive groundbreaking developments that transform industries and improve lives.

As a trusted partner, we provide industry leaders with the highest-quality materials and deep technical expertise – turning challenges into solutions. Together, we are shaping the future of technology.

Specialty materials: the catalyst for boundless innovation

From large panels for multi-chip integration to thin interposers with ultra-high TGV density near the die, SCHOTT empowers the semiconductor and datacom industries with a comprehensive range of specialty glass and materials. As trusted glass experts, we enable rapid advancements in cutting-edge technologies to unleash the future of high-performance.

Advanced IC-packaging and integration

- Glass carrier: Wafers and panels for IC manufacturing and advanced packaging including fan-out wafer and panel level packaging (FO-WLP/FOPLP)

- Glass core substrate: Glass panels designed for structuring and lamination to create high-density advanced packaging substrates and interposers

Front-end process

- Plasma etch equipment: Quartz materials serving as key materials for chamber components

- Epitaxy equipment: Quartz glass for components in epitaxy chambers

- Diffusion equipment: Fused quartz materials for diffusion processes

Lithography

- Display lithography: Glass in technologies for the production of displays

- IC lithography: Glass for applications in the manufacture of integrated circuits (ICs)

Sensors

- Pressure sensors: Glass in pressure monitoring of semiconductor processes

- Actuators: Glass in enabling long-term precision of piezoelectric actuators

- Gas sensors: Glass in environmental monitoring and safety applications

- Temperature sensors: Glass for fiber optic temperature sensing

- Positioning sensors: Fiber optic light guides for interferometric measurements

Optoelectronics

- Laser components: Glass for applications in data-communication and sensor technology

- Photodetectors: Glass for sensors for light detection

- LEDs: Glass in lighting and display technologies

MEMS

- MEMS packaging: Glass solutions for the encapsulation of MEMS components

- MEMS mirrors: Glass in optical systems and scanners

- Pressure sensors: Glass for pressure sensors in automotive and medical technology

High-frequency technology

- RF filters: Glass for high frequency filters in telecommunication applications

- Antennas: Glass in wireless communication systems

- Radar components: Glass in automotive and aerospace applications

Versatile specialty glass for advanced applications

Specialty glass is a remarkably versatile material that plays a vital role in high-tech industries. At SCHOTT, our materials range from ultra-thin and ultra-flexible to ultra-tough glass, designed to meet the demands of cutting-edge applications.

As a pioneer in specialty materials, we offer an extensive portfolio of materials and advanced processing capabilities – catering specifically to the semiconductor and datacom sectors.

High-purity quartz is a key material in semiconductor manufacturing, especially used throughout the front end process. Schott supplies quartz base materials ranging from standard purity to ultra-high purity and near net shape, customized to meet the requirements of advanced processes.

Substrates, wafers and panels

Substrates and wafers for semiconductor production.

- Carrier wafers

- Carrier panels

- Glass panels for glass core substrate

- Structured wafer (TGVs and cavities) prototyping

Glass optical fibers

Fiber optic solutions for optical sensing and metrology

- Flexible light guides

- Fiber optic sub-assemblies

- Flexible imaging bundles

Quartz glass base materials

High-purity quartz is essential for advanced semiconductor front-end processes. We offer a wide range of near-net-shape ring and component geometries – from high-volume production to single-piece lot sizes – supporting the consumable business of leading equipment manufacturers. Our processes and capacity are designed to absorb typical semiconductor demand swings, ensuring stable supply even in volatile market conditions.

-

Near-net-shape manufacturing

-

Etch rings (focus / edge / cover) for plasma etch equipment

-

Flanges and liners for epitaxy and diffusion equipment

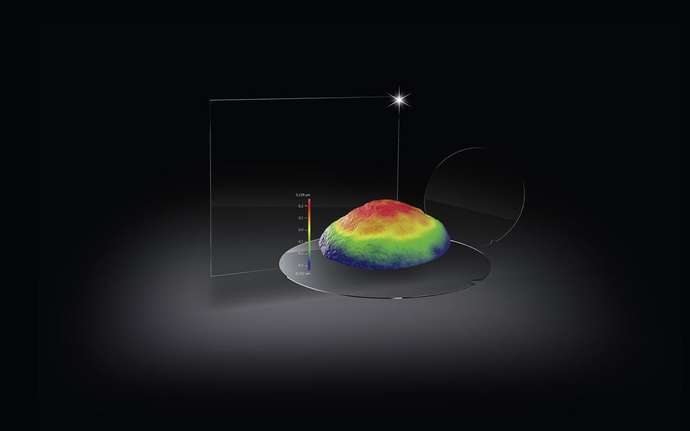

ZERODUR® glass-ceramic

ZERODUR® glass-ceramic delivers unmatched thermal stability for advanced lithography systems. Its near-zero thermal expansion ensures precise wafer positioning and consistent performance under extreme conditions. With exceptional homogeneity and mechanical strength, ZERODUR® is the foundation for critical components like reticle and wafer stages. Trusted in EUV lithography, it enables the accuracy required for next-generation semiconductor manufacturing.More about ZERODUR® glass-ceramic