Optical Metrology

Generally, optical metrology approaches follow these steps:

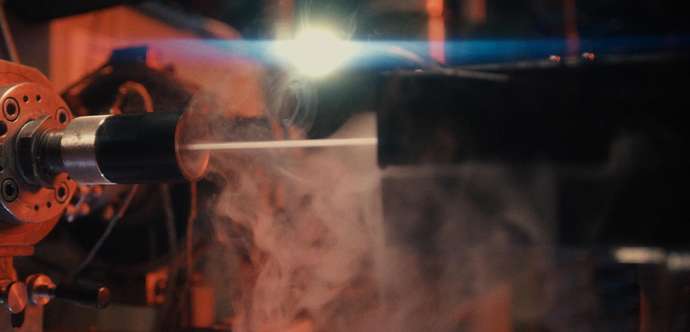

Illumination

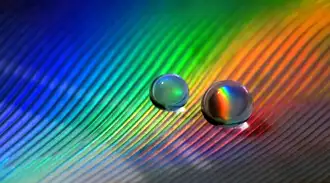

A light source, often a laser or other coherent light emitter, is used to illuminate the object. Optical elements like fiber optic light guides, lenses, mirrors, or beam splitters can be used to control and direct the light path used for illumination.

Interaction

When light interacts with the object, the object’s characteristics cause it to change in various ways. This can modify the way the light is reflected, refracted, or absorbed, which creates changes in the intensity, wavelength, phase, or polarization of the light.

Detection

Detectors or sensors capture the modified light after it has interacted with the object. Measuring changes in the light’s properties provides important insights into the object's properties.

Optical metrology techniques

Typical applications for optical metrology

Thanks to its ability to provide precise and accurate measurements, a wide variety of industries and scientific fields rely on optical metrology. Some prominent application areas include:

Specialty glass in optical metrology

SCHOTT’s specialty glass components and subassemblies — including fiber optic light guides, optical materials and components, and hermetic packaging — are essential in advancing optical sensing and metrology, where precision and accuracy are paramount. Our specialty glass materials are engineered to possess unique combinations of optical properties, such as low dispersion and high transmittance, which enable cutting-edge sensors and measurement instruments. By facilitating light manipulation, specialized glasses and components are empowering advanced signal detection and precise measurement.

SCHOTT´s products for optical metrology and sensing

Fiber optic bundles

Fiber optic bundles play a crucial role in optical metrology by carrying light from a source to a measurement device or from an object under scrutiny to a detector. Whether guiding light and images around a corner, out of a tight space, or away from a hot, dark, or challenging area, fiber optics are critical for many of the world’s most advanced technologies.

Optical and filter glass

We have an extensive range of optical and filter glass carefully developed to improve precision and accuracy in metrology applications. Our more than 120 different optical glasses can be used to fabricate the lenses, mirrors, and other components that form the backbone of the high-precision imaging systems used in metrology. In addition, SCHOTT's specialized filter glasses — including bandpass, longpass, shortpass, multiband, and contrast enhancement filters — help control light transmission and isolate specific wavelengths. This high-performance filter glass helps improve contrast and measurement accuracy in optical metrology. Our meticulously engineered glasses are helping shape the future of metrology by making it possible to set unparalleled benchmarks for accuracy and dependability.

Optical components and coatings

SCHOTT’s optical metrology solutions also include precision-engineered optical components and coatings that enhance measurement accuracy. We carefully craft optical components such as lenses and mirrors to provide excellent imaging quality, which is essential for high-precision metrology systems. SCHOTT's advanced coatings can help reduce reflections, improve light transmission and attenuate surface interference, ensuring minimal measurement distortion and maximum accuracy when performing measurments with light. These precision-engineered components and coatings are crucial in metrology system design, facilitating unparalleled accuracy and dependability for measurement and analysis.

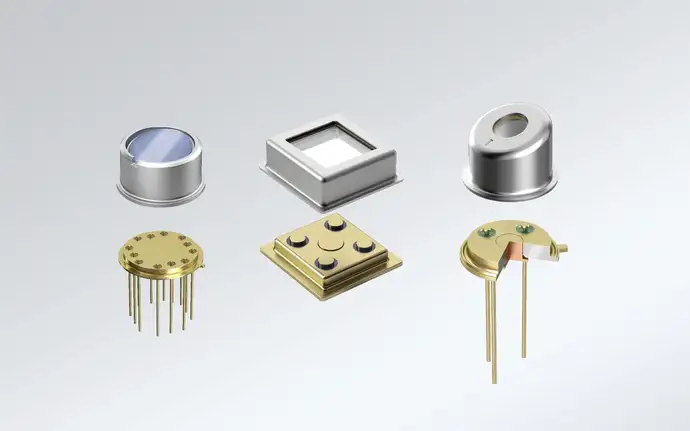

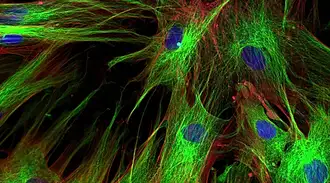

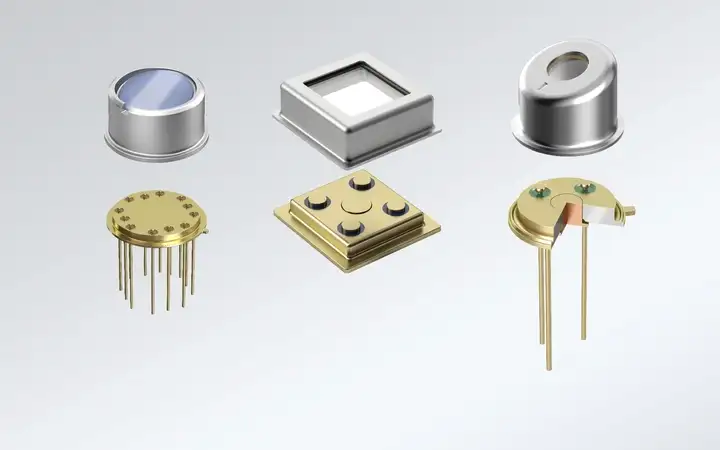

Hermetic packaging and components for optical sensors

Packaging and electrical feedthrough components play an essential role in ensuring reliability and functionality of optical sensors and metrology devices. Vacuum-sealed packages offer protection from external influences such as moisture, dust, and vibration as well as light interference. They also provide proper alignment of optical components, which is crucial for accurate and reliable measurements. Hermetic packaging components can include connectors or interfaces that enable communication via optical signals, allowing sensors to be integrated into a broader system.SCHOTT offers a variety of packaging options, such as custom-designed through-hole or SMD packages as well as high-performance optical lens or window caps to protect UV/VIS/IR sensors. Our Viewport® and Viewcell® bioreactor interfaces allow optical sensors to be used in bioprocessing.