Bioscience experience and expertise to help you succeed

Bioscience at SCHOTT MINIFAB

Our bioscience team manages all activities and capabilities associated with biological or assay workflows and reagent production as part of our contract design, development and manufacturing activities. Combining cross-functional expertise and state-of-the-art technology our bioscience team can help enable a better outcome for your design solutions from the start of your product development journey.Our philosophy for consumable product development is, a better understanding of an assay workflow leads to a functional design. This in turn informs the instrument interface and design requirements. Taking this holistic approach can reduce steps, save time, and improve the likelihood of success for your product development, and the ability to seamlessly scale to high-volume manufacture.

The value of bioscience for your product development

With a dedicated team of scientists with diverse experience and expertise, we can quickly understand and adapt our approach to best meet the needs or your project. Whether it be early-stage concept or development activities or later stage design transfer and industrialization of your prototype (low volume pilot line production to full-scale manufacturing), our bioscience team is here to help you realise your product vision.With function-forward thinking, you can experience the full value of SCHOTT MINIFAB’s bioscience expertise from anywhere in the world.

In general, we split bioscience into three key capabilities:

Assay translation

This involves the adaptation of assay workflows for on-cartridge implementation, conducted within the scope of design and development activities. This process considers intended use, reagent compatibility, and manufacturing constraints to inform the overarching product vision and development.We work in partnership with our customers to adapt their assays into cartridge-compatible workflows that align with product vision and functional requirements. This process is conducted as part of the design and development activities and involves close cross-functional collaboration with our in-house engineering teams to develop fit-for-purpose designs. This holistic approach enables early risk identification and supports efficient, high-quality product development and maximizes likelihood of success.

Experience fast design spins by identifying and implementing necessary changes quick and keep your product development moving forward. Take a science-first approach to access the agility you need to reach your goals.

Benchmarking

We use your assay as the benchmark for assessing the success of the translation activity, identifying where surrogate reagents or samples can be used for proof-of-principle testing to save precious clinical or expensive samples/reagents.Uncover unknowns

Through these activities our team helps to uncover your unknown unknowns and de-risk the design and development activities early to enable efficient and effective product development to maximize your success.Reagent integration

Reagent integration refers to the process development for reagent industrialization and integration into a cartridge manufacturing strategy. It ensures reagent specifications and processing requirements are defined and aligned with manufacturing needs, and considers in-process QC steps of reagent quality ahead of release to production. These activities support realization of consistent quality, functional performance, and specification compliance across manufacturing batches.A well-defined and controlled process minimizes variability, supports traceability, and enables efficient scale-up and production planning.

Our team balances economies-of-scale with risk-and-yield considerations to establish the best manufacturing strategy to meet our customer’s immediate need leveraging our pilot line capabilities, with the opportunity to progress to scaled manufacturing.

Through our ability to formulate our customer’s reagents on the same site as the device is manufactured we enable an agile production schedule to adapt to our customer needs, and simplify their manufacturing process through a single source supply.

Reduce your risks and costs with bioscience in mind from the start of your product development journey.

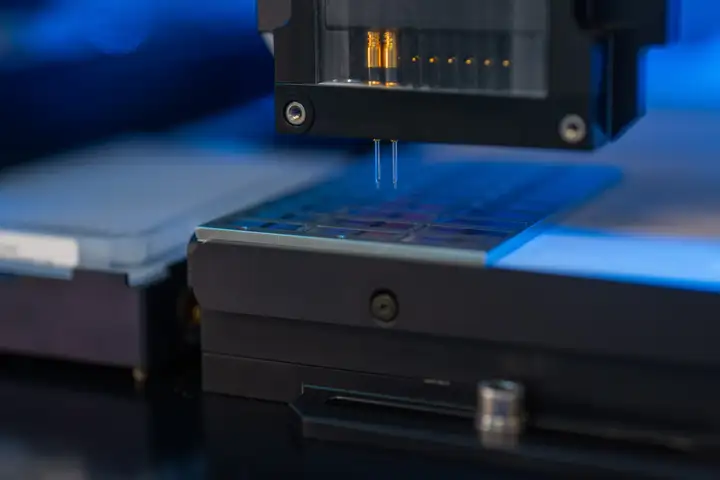

Microarrays

We bring together scientific and engineering expertise to deliver custom microarray platforms for diagnostics and life sciences. Our team specializes in optimizing every aspect of microarray design – from biomolecule selection and spotting strategies to surface activation, attachment chemistry, and dispense buffer formulation. We ensure probe integrity and stability throughout production, assembly, and packaging, developing tailored methodologies to extend shelf life and preserve quality.With roots in the Human Genome Project, our team has decades of experience advancing proprietary dispense technologies that set the standard for precision, throughput, and flexibility. More than just technology, we offer a collaborative, integrated approach that accelerates development, reduces time to market, and ensures high-performance, cost-effective microarray solutions.

Considerations for manufacturability

We understand reagent materials and compliance – licensing, permits, CTQ specifications, inwards goods QC – and a deep understanding of reagent cost drivers in product cost models. Our experienced team will support you throughout product development journey with key considerations including

- Formulation and production (reagent batch considerations – cleanliness, storage vessel and equipment compatibility, mixing specifications)

- Environment and handling (bulk reagent stability, exposure to light and humidity etc)

- Quality and testing (in-process and out-going QC within defined limits, lot calibration, sampling and release testing)

- Packaging and shelf-life (kitting and shelf-life strategy, storage requirements for intermediates and finished goods)

We will work with you to establish a reagent integration process that is aligned with the manufacturing process, for seamless manufacturing.

Learn more about contract product development

Learn more about contract manufacturing

We work with you to define, document and deliver

Our experienced and established in-house capability provides our customers with the reassurance that we understand the challenges with the transition from development to pilot line to manufacturing, and subsequent scaled manufacturing. Our team highlights key challenges early to de-risk these activities in the early phases of process development and reagent formulation and industrialization.